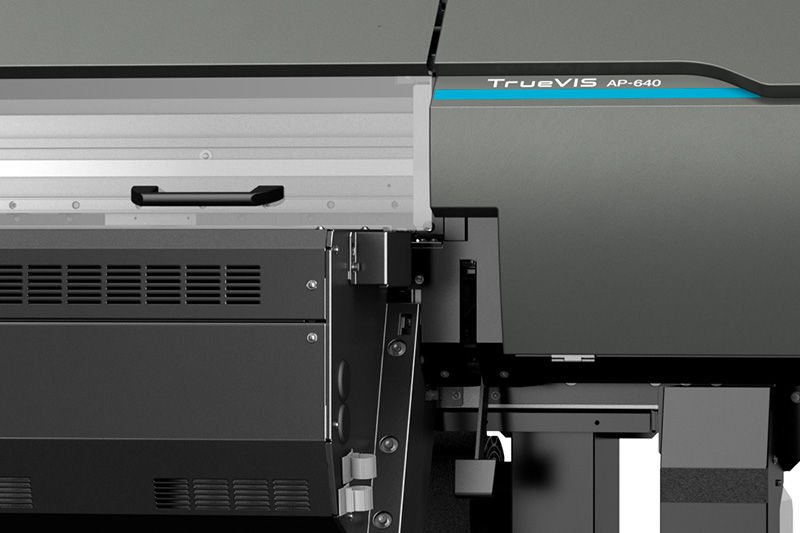

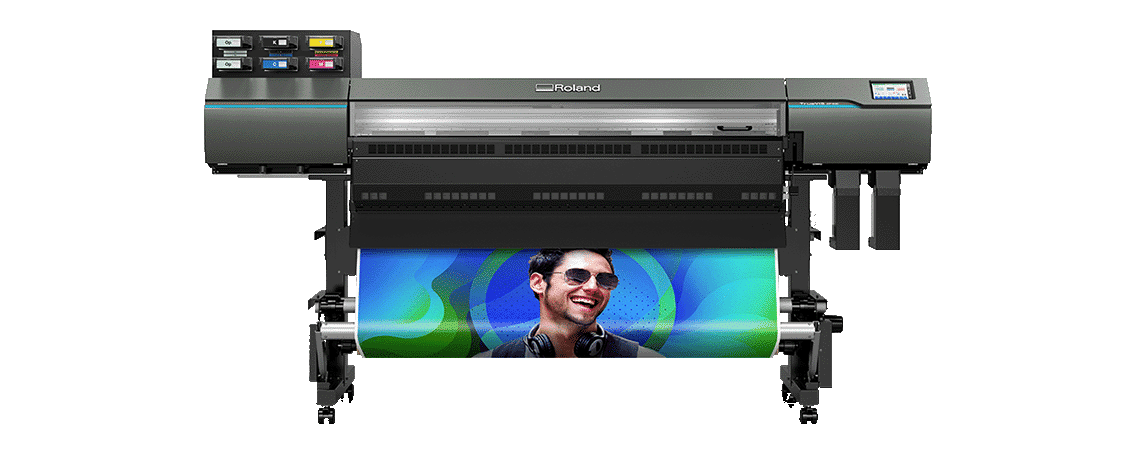

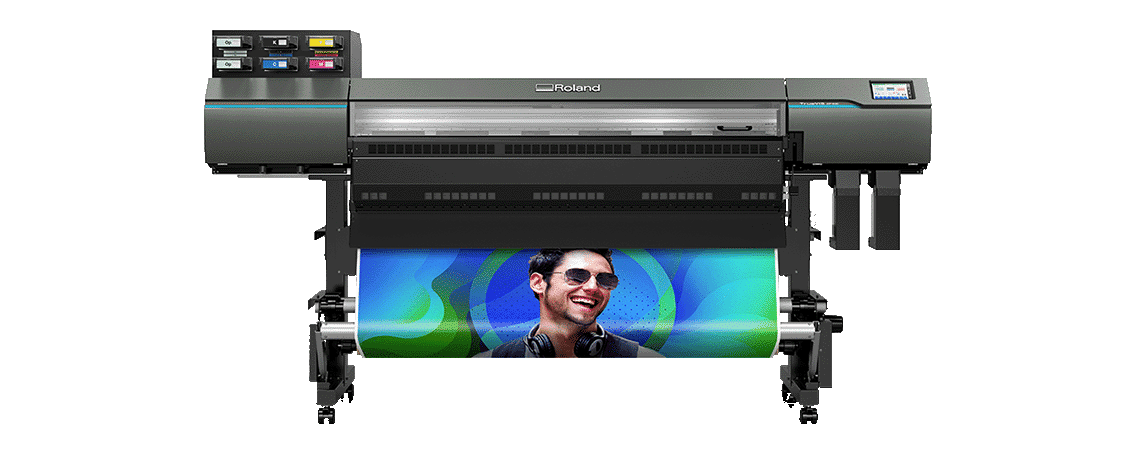

TrueVIS AP-640 Resin Printer

Build and expand your sign and graphics business with a wide range of applications, low running-costs, and the quick drying benefits of Roland DG's first resin printer.

- Dual, staggered printheads with variable dot printing and True Rich Color presets offer natural, vibrant print results with higher color saturation

- Water-based TrueVIS Resin Ink provides quick-drying, scratch-resistant, and safe results on a wide range of media

- Legendary Roland DG machine reliability, service, and support now available in a resin ink printer

WINNER

Keypoint Intelligence BLI Pick Award

Keypoint Intelligence Shares

Why They Awarded the AP-640

Resin Printing

Just Got So Much More Vivid and Exciting

Until now, resin printing was associated with flat, uninspiring color. Enter the TrueVIS AP-640 that’s redefining resin printing with high color saturation on a wide range of materials from uncoated PVC to non-PVC media. It features new TrueVIS resin ink and advanced machine features to optimize color reproduction on vinyl, paper, film, and specially formulated fabrics — expanding your graphics to include flags, roll-up screens, textiles, wallpapers, and so much more.

Print hospital wall graphics that are not only visually stunning, but also safe enough for use in the most sensitive health settings.

Enhance the educational experience with environmentally friendly wall graphics that inspire, stir the imagination, and spark creativity.

Produce bright, colorful graphics that freshen up supermarket walls and create a warm and inviting experience for shoppers.

Add your unique style to a variety of packaging with labels and stickers that feature your specific brand.

Safely print vibrant designs for interior home decoration applications.

Extend your designs to multiple surfaces with graphics that make your customers feel welcome.

Print brilliantly colored, detailed vehicle graphics with resin inks that dry instantly and allow for quick job turnaround.

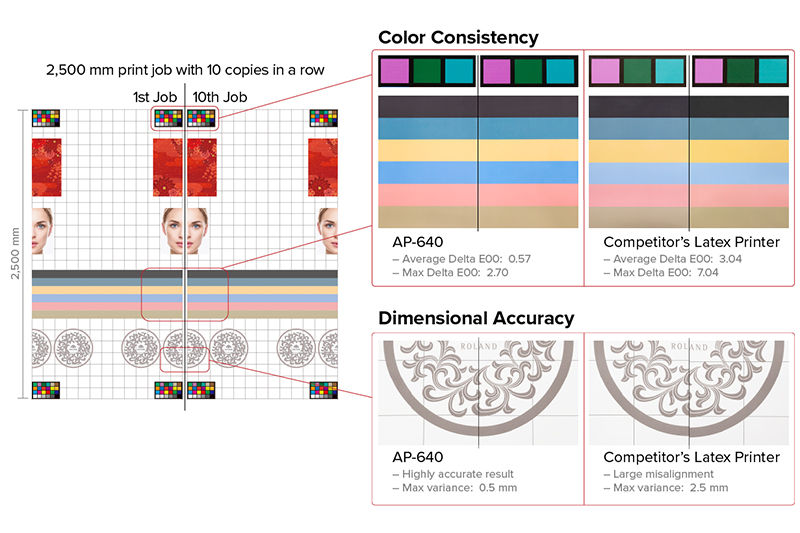

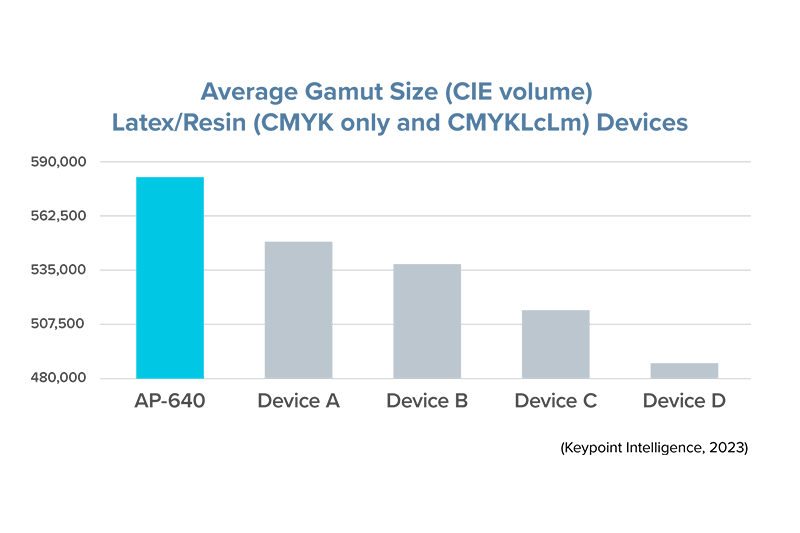

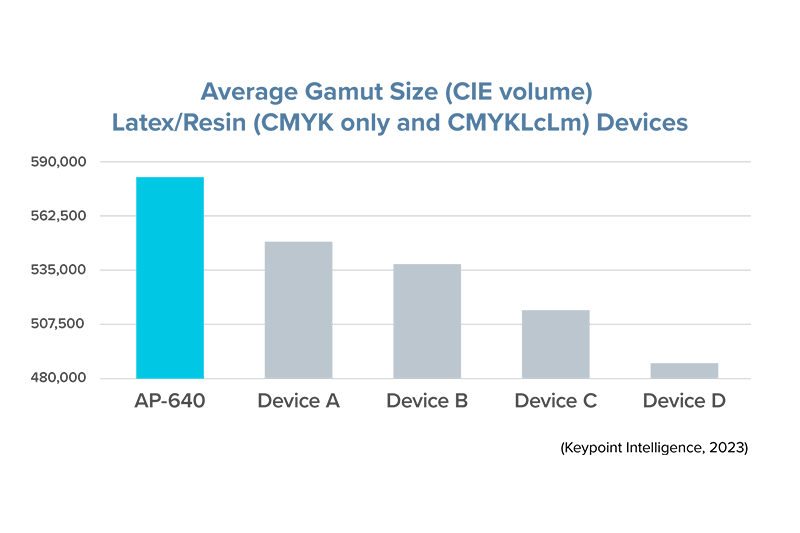

The Widest Color Gamut in its Class

TA Inks boast the widest gamut and most vibrant colors of any 4-color resin/latex wide-format printer.* The TrueRichColor 3 print setting maximizes the potential of the printer and inks, so you can produce highly impactful graphics that combine vivid colors and natural tones that viewers are sure to love.

Spot Colors That Are Spot-On

The AP-640 offers excellent color reproduction capabilities, allowing you to match brand colors, even those that are traditionally difficult. Consistent, high-quality output can be produced in short turnaround times, keeping your customers coming back for more.

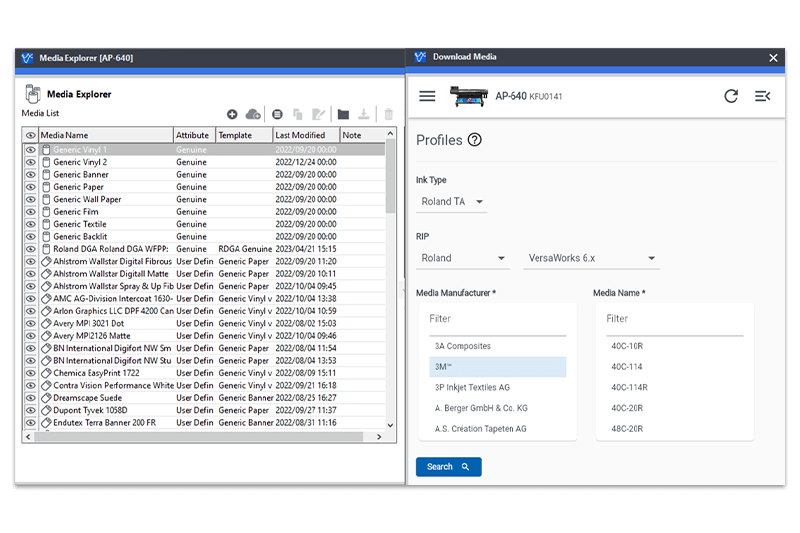

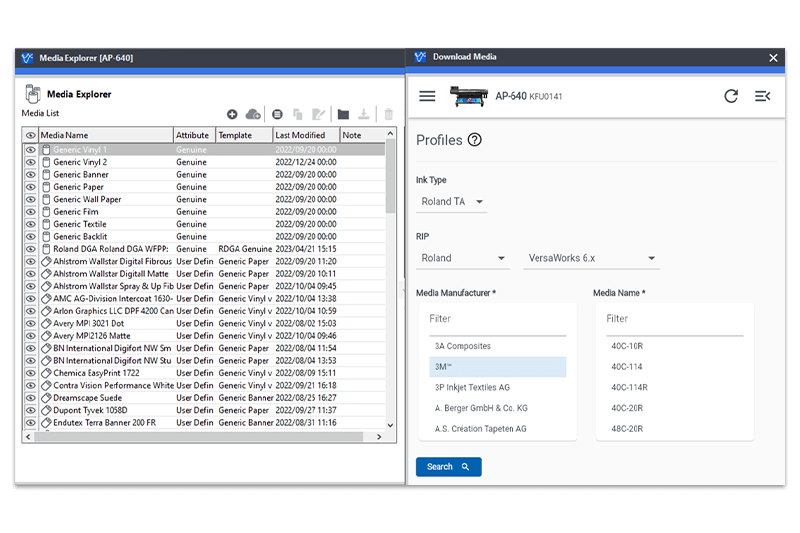

Media Profiles Ready to Go

More than 300 popular media profiles are ready for use with the AP-640 and TA Ink, including PVC and non-PVC media, such as wallpaper, paper, film, vinyl, roll-up screens, textiles, canvas, heat transfer paper and more – so you can be ready to produce a wide range of applications right from the start.

The highly concentrated color pigmentation of TrueVIS Resin Ink enables heavier color saturation than conventional resin inks and printers for optimum graphic impact on paper, fabric, canvas, wallpaper, non-PVC materials, and other media.

Learn More >

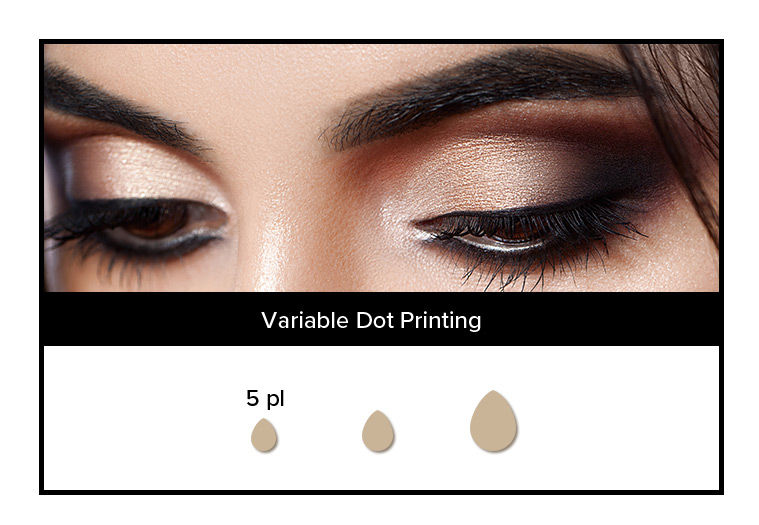

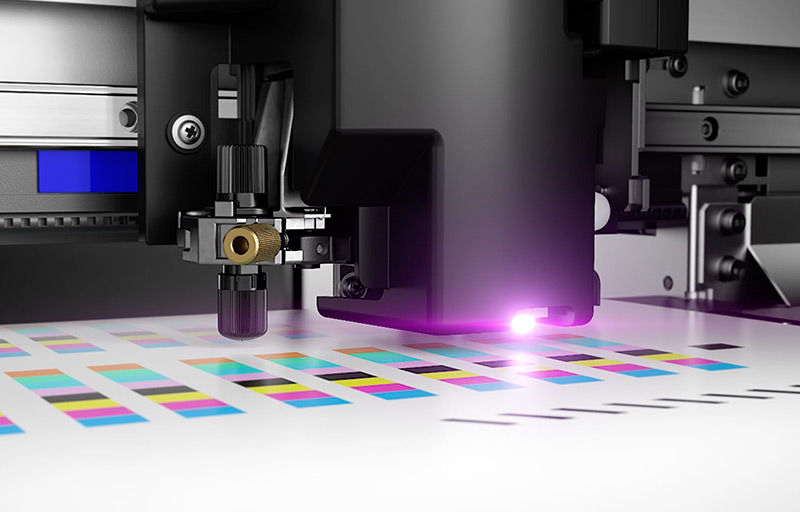

Variable Dot Printing

TrueVIS resin printers benefit from hundreds of dedicated, media-specific printing profiles that control optimal ink volume and drying temperature. An optimizer prepares the media surface facilitating the formation of precise dots while variable dot control technology fires three types of ink droplets to create unparalleled image quality, producing natural beauty and vividness never before seen in a resin ink printer.

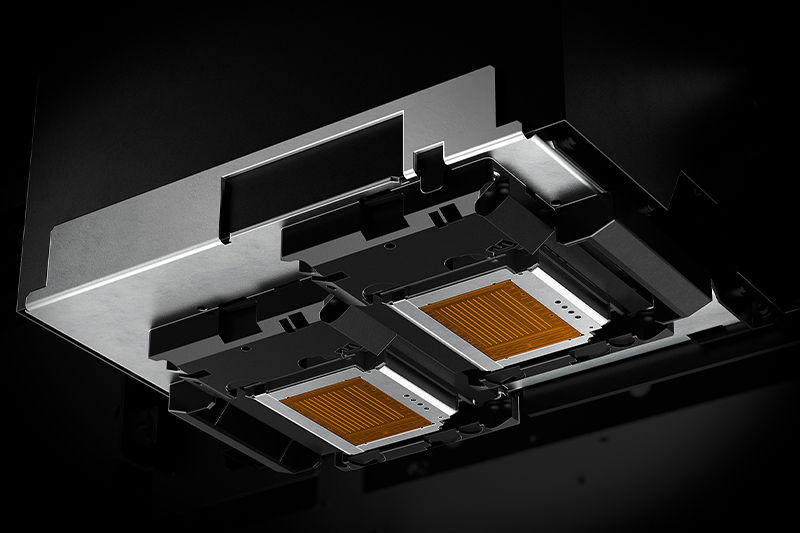

Dual Staggered Printheads for Resin Inks

Printheads are arranged in a dual, staggered formation with an optimizer printhead that preps the media surface for the CMYK printhead. This enables ink droplets to form a finer dot, resulting in more precise color and images.

Touch-Panel Operation

A 7-inch, full-color touch panel with intuitive settings and functions makes print operations simple. Clearly defined icons for set-up, maintenance, print volume, consumables, print status, and more allow for a convenient, streamlined workflow.

High-Productivity Dryer Unit

Newly designed drying unit allows prints to dry quickly and completely before proceeding to the next process, saving hours of production time.

Automatic Gap Adjustment

Media gap and feed compensation can now be adjusted automatically with a single button. The AP uses optical registration technology to ensure print accuracy and avoid variations in output.

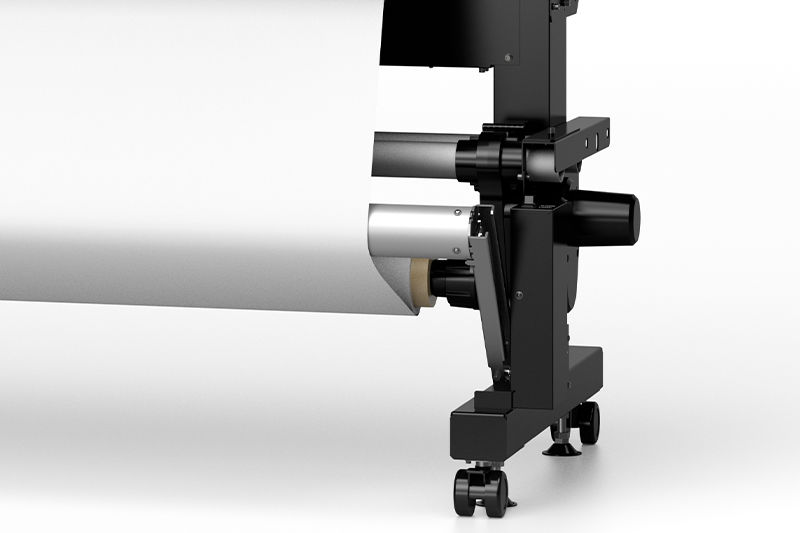

Included Take-Up Unit

An adjustable take-up provides print stability for a wide variety of popular media. It also allows easy installation of a loading platform for clean, efficient media collection.

Instant Drying

Drying time is virtually eliminated thanks to a built in heating unit.

Speed is Key

Dual, staggered Piezo printheads receive optimizer and ink in tandem to maintain optimal workflow.

Improved Ink Capacity

New 700 ml high-capacity ink pouches are easily replaceable, supporting economical and environmental printing operation.

Resin Ink Re-imagined

Our newly developed water-based resin ink and innovative True Rich Color 3 preset works together to ensure vibrant color and natural-looking print quality time and again.

Versaworks 7

The AP-640 comes with user-friendly, feature-filled RIP software, and Roland DG Connect print operation app.

Low Running Costs

High pigment, quick drying resin inks let you produce more output with less ink, effectively reducing running costs.

Included VersaWorks 7

RIP Software

RIP Software

The latest edition of the world’s most popular RIP software seamlessly combines with our new AP-640 resin printer technology to effortlessly manage your print output.

- Five print queues, five hot folders and unlimited queue settings.

- New Job Assistant function to layout and edit cut lines in VersaWorks 7 for dual machine print-then-cut workflows.

- Advanced and easy cropping, tiling, nesting and other features.

- Match color output between different printers and print modes from a single printer with Printer Color Match Settings that integrate profiling tools such as the i1 Pro3 and new VW-S1 color measuring tool.

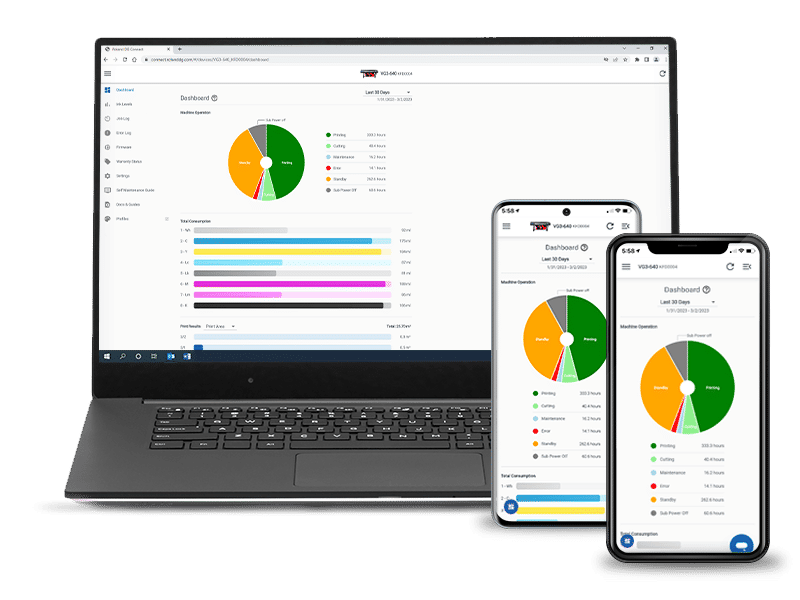

Roland DG Connect App

For Everything Creative

Gain a detailed understanding of your entire print operation while keeping your device running at optimum performance with a user-friendly app specially designed to integrate seamlessly with your TrueVIS AP-640. Reduce downtime and improve efficiency with a machine monitoring assistant that works in complete harmony with your device.

Powering the Future of Printed Signs and Graphics

Multi-award winning TrueVIS printers and printer/cutters, now available in a variety of models and print production solutions, have become the benchmark for color quality and performance in the large-format sign and graphics industry. The professional’s choice for building brand consistency, building the highest quality print output, and building confidence in your business, the AP-640 is designed for passionate professionals like you, who need quality, dependability, and versatility to achieve new levels of success.

GREENGUARD Gold Certified

TrueVIS Resin Ink

New TrueVIS Resin Ink not only images beautifully and dries quickly, it’s also GREENGUARD Gold certified. That means it meets some of the world’s most rigorous chemical emissions standards to help reduce indoor air pollution and the risk of chemical exposure. With its low VOC (Volatile Organic Compounds) emission level, TrueVIS Resin ink is safe, environmentally friendly, and acceptable for use in even the most sensitive indoor environments, including schools, hospitals, and other types of healthcare facilities.

Protect Your Investment

- Factory-trained service engineers

- Quick installation and first-time set-up

- Expert advice and training

Additional Information

Specifications

TrueVIS AP-640

| Model | AP-640 | |

|---|---|---|

| Printing method | Piezo ink-jet method | |

| Media | Width | 259 to 1625 mm (10.2 to 64 in.) |

| Thickness | Max. 1.0 mm (0.039 in.) with liner | |

| Roll outer diameter | Max. 250 mm (9.8 in.) | |

| Roll weight | Max. 45 kg (99 lb.) | |

| Core diameter | 76.2 mm (3 in.) or 50.8 mm (2 in.) | |

| Printing width1 | Max. 1615 mm (63.5 in.) | |

| Ink | Type | Resin ink 700 ml pouch |

| Colours | Four colours (cyan, magenta, yellow, and black) and optimizer | |

| Print resolution (dots per inch) | Max. 1200 dpi | |

| Ink drying system2 |

Print heater set temperature: 25 to 45°C (77 to 113°F) Dryer set temperature: 70 to 110°C (158 to 230°F) |

|

| Connectivity | Ethernet (100 BASE-TX / 1000 BASE-T, automatic switching) | |

| Power-saving function | Automatic sleep feature | |

| Rated Input |

Printer: 200-240 Va.c. 50/60 Hz 3 A Dryer 1: 200-240 Va.c. 50/60 Hz 10 A Dryer 2: 200-240 Va.c. 50/60 Hz 10 A |

|

| Power consumption | During operation | Approx. 4000 W |

| Sleep mode | Approx. 65 W | |

| Acoustic noise level | During operation | 69 dB (A) or less |

| During standby | 53 dB (A) or less | |

| Dimensions (with stand) | 2886 mm x 836 mm x 1550 mm (113.7 in. x 33 in. x 61.1 in.) | |

| Weight (with stand) | 266 kg (587 lb.) | |

| Environment3 | During operation | Temperature : 20 to 30°C (68 to 86°F), Humidity : 20 to 80 % RH (no condensation) |

| Recommended Environment | Temperature : 20 to 25°C (68 to 77°F), Humidity : 40 to 60 % RH (no condensation) | |

| Not operating | Temperature : 5 to 40°C (41 to 104°F), Humidity : 20 to 80 % RH (no condensation) | |

| Included items | Dedicated stand, power cords, dryers, media take-up unit, media holders, separating knife, replacement blade, cleaning liquid bottle for maintenance, drain bottle, User's Manual, software (VersaWorks, Roland DG Connect), etc. | |

- Specifications, designs and dimensions listed may be subject to change without notice

- *1: The length of printing is subject to the limitations of the program.

-

*2: Warm-up is required after power up. This may require 5 to

20 minutes, depending on the operating environment.

Depending on the ambient temperature and media width, the preset temperature may fail to be reached. - *3: Use the machine in an operating environment within these ranges. Also, printing in the recommended environmental conditions (A) is recommended to prevent or reduce any possible differences in print quality depending on media

Datasheet

Download Your AP-640 Datasheet

Get your digital guide to all the features, applications, benefits and specifications of the Large-Format Inkjet Printer.

Download Brochure